Prefix Settings

The Prefix Settings feature in the Inventory module allows users to configure and manage automatic numbering prefixes for various inventory transactions. This ensures standardized document numbering, easier tracking, and improved organization of inventory records.

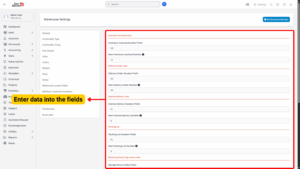

Accessing Prefix Settings

To access the Prefix Settings page:

Step 1: Go to Settings under the Inventory module from the left sidebar.

Step 2: Select Prefix Settings.

Step 3: Enter the required prefix and numbering details in the available fields.

Step 4: Click Save to apply the changes.

1. Inventory Received Note

a) Inventory Received Number Prefix

– Define the prefix used for Inventory Receiving Vouchers.

– Example: NK- will generate numbers like NK-0001, NK-0002, and so on.

b) Next Inventory Received Number

– Set the starting number for receiving note numbering.

– If set to 1, the numbering will restart from the beginning.

– The system will automatically increment by 1 after each new Inventory Receiving Note.

2. Inventory Delivery Note

a) Inventory Delivery Number Prefix

– Define the prefix for Inventory Delivery Notes.

– Example: XK- will generate numbers like XK-0001, XK-0002, etc.

b) Next Inventory Delivery Number

– Set the starting number for delivery note numbering.

– Automatically increases by 1 after a new delivery note is created.

3. Internal Delivery Note

a) Internal Delivery Number Prefix

– Define the prefix for Internal Delivery transactions.

– Example: ID-.

b) Next Internal Delivery Number

– Set to 1 to restart numbering from the beginning.

– The system auto-increments by 1 after each new internal delivery transaction.

4. Packing List

a) Packing List Number Prefix

– Define the prefix for Packing List transactions.

– Example: PL-.

b) Next Packing List Number

– Set to 1 to restart numbering.

– The system auto-increments after each new packing list is created.

5. Receiving – Exporting Return Order

a) Receipt Return Order Prefix

– Prefix for return notes of received goods.

b) Next Receipt Return Order

– Set to 1 to restart numbering.

– Automatically increases after a new receipt return order is created.

c) Delivery Return Purchasing Goods Prefix

– Prefix for return notes of delivered goods.

d) Next Delivery Return Purchasing Goods

– Set to 1 to restart numbering.

– Automatically increases after each creation.

6. SKU Prefix

SKU Prefix

– This prefix is automatically added in front of the SKU code entered by the user during the Add Item process.

– Ensures consistent SKU formatting throughout the system.

– Example: If the prefix is INV- and the entered SKU is 001, the final SKU becomes INV-001.

7. Lot Number

a) Automatically Generate Batch Numbers

– If this option is checked, the system will auto-generate batch numbers in Inventory Receiving Notes.

b) Lot Number Prefix

– Prefix for batch/lot numbers.

c) Next Lot Number

– Set to 1 to restart numbering.

– Automatically increases after a new batch number is generated.

8. Serial Numbers

a) Next Serial Number

– Set the starting number for serial numbers.

– Automatically increments after each new serial number is created.

b) Serial Number Format

Choose one of the following formats:

– Number Based (0000001)

Example: 0000001, 0000002, 0000003 …

– Date-Based (YYYYMMDD000001)

Example: 20250414000001, 20250414000002 …

This format allows for better tracking by including the date of creation in the serial number.