Internal Delivery Note Documentation

Overview

The Internal Delivery Note (IDN) feature is used to record and manage the transfer of items between warehouses within the same organization. This process ensures accurate stock tracking, maintains inventory balance across multiple storage locations, and supports proper accounting of stock movements.

By using internal delivery notes, you can:

– Track stock movement from one warehouse to another.

– Maintain proper audit trails for inventory transactions.

– Ensure accurate real-time stock updates.

– Support internal logistics and operational efficiency.

1. Prerequisites

Before creating an internal delivery note, ensure the following:

1. You have the required user permissions to access the Inventory module.

2. Warehouses are already set up in the system.

3. An approval process is configured if your organization requires approval for internal stock movements (optional).

4. Items exist in the source warehouse with sufficient available quantity.

2. Create an Internal Delivery Note

Step 1. (Optional) Configure Approval Process

1. Go to Approval Settings under Settings.

2. Set up the approval workflow for Internal Delivery Notes, if required.

3. Assign approvers, conditions, and notification rules.

Info

If no approval process is required, the delivery note can be approved immediately after saving.

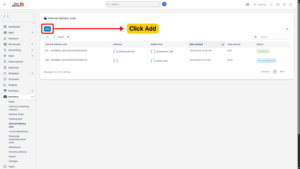

Step 2. Access the Internal Delivery Note Menu

1. Navigate to Inventory module from the left sidebar.

2. Click Internal Delivery Note.

3. Select Add to create a new record.

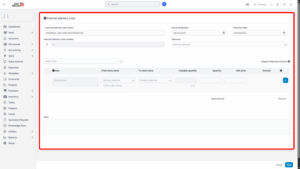

Step 3. Fill in the Required Details

| Field | Description |

|---|---|

| Internal Delivery Note Name | Auto-generated name for easy reference. |

| Internal Delivery Note Number | Auto-generated number based on Prefix Setting. |

| Accounting Date | The date the transaction will be recorded in accounting reports. |

| Voucher Date | The actual date when the stock transfer takes place. |

| Deliverer | Person responsible for carrying out the transfer (e.g., warehouse personnel). |

| Select Item | Choose the item to be transferred from the dropdown list. |

| From Stock Name | Source warehouse where the item is currently stored. |

| To Stock Name | Destination warehouse to which the item will be moved. |

| Available Quantity | Auto-filled with the current stock quantity in the source warehouse. |

| Quantity | Quantity to be transferred. Must not exceed the available stock. |

| Note | Optional field to add additional remarks or internal references. |

1. Click Add to include the selected item in the transfer list.

2. Click Remove to delete an item from the list if needed.

Step 4. Save the Internal Delivery Note

1. After entering all required fields, click Save.

2. The note will be saved in Not yet approved status by default.

Step 5. Approval (If Applicable)

1. Open the newly created Internal Delivery Note.

2. Click Send Approve Request.

3. Approver will review and approve or reject the transfer.

4. Once approved, the system will:

– Deduct the quantity from the source warehouse.

– Increase the quantity in the destination warehouse.

3. Edit an Internal Delivery Note

Tip

Only Internal Delivery Notes with Not yet approved status can be edited.

Steps:

1. Go to Internal Delivery Note under the Inventory module.

2. Select the note you want to edit.

3. Click Edit.

4. Make the necessary changes to fields such as Deliverer, Item Quantity, or Note.

5. Click Save to update the document.

Once the IDN is approved, no further edits can be made unless it is reverted.

4. Delete an Internal Delivery Note

Tip

Only Internal Delivery Notes with Not yet approved status can be deleted.

Steps:

1. Go to Internal Delivery Note under the Inventory module.

2. Select the note to delete.

3. Click Delete.

4. Confirm the deletion in the pop-up confirmation message.

5. The record will be permanently removed.

Note

Deleting an approved internal delivery note is not allowed to maintain accurate stock history. You must reverse or adjust through a new transaction instead.

5. View Internal Delivery Note Details

1. Go to Internal Delivery Note list.

2. Select the desired record.

3. Click View.

4. From here, you can:

– Review all delivery details.

– Check transfer quantities and warehouse movement.

– Track approval status.

– Print or export if needed (depending on system configuration).

6. Stock Movement Behavior

When an Internal Delivery Note is approved:

1. Stock is deducted from the source warehouse.

2. Stock is added to the destination warehouse.

3. The movement is recorded in inventory history for reporting and audit purposes.

4. Serial numbers or batch numbers (if enabled) are transferred along with the item.